“If we had computers that knew everything there was to know about things—using data they gathered without any help from us—we would be able to track and count everything, and greatly reduce waste, loss and cost. We would know when things needed replacing, repairing or recalling, and whether they were fresh or past their best.”

– Kevin Ashton, coined the term ‘Internet of Things’

Internet of Things (IoT) has gained more and more significance as it allows an object to represent itself digitally, where anything can be connected and communicated in an intelligent manner.

- Software development companies have enabled industries to integrate IoT predictive maintenance solutions to reduce downtime

Value Addition of IIoT

The Industrial IoT- a subset of internet of things has given new dimensions to operational technology which includes Remote Management; Operational Analytics and the most important value add- Predictive Maintenance.

Old aging Industrial equipment has an average life span between 30-60 yrs,replacing the equipment has proven expensive and unexpected breakdown results in loss of productivity as well as profit.

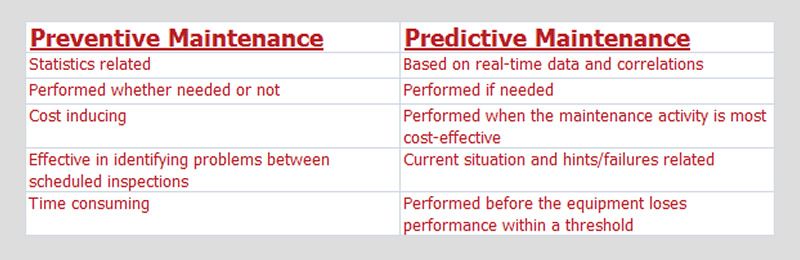

Until now there was a huge dependency on previous statistics and taking a best shot at how to prevent problems, also known as preventive maintenance.

Want to integrate IoT technologies to increase your commercial vitality?

Reach out to our experts for winning solutions

What is Preventive Maintenance and how is it different from Predictive Maintenance?

Imagine you purchased a new car three months ago. To get around your daily activities you alternate between your motorbike, sometimes walking and driving the new car. The service manual says that the engine oil must be replaced every three months or 1500 kms, you have so far covered around 950 kms. But since it has been 3 months you purchased the car; you take your car to the workshop for an oil change so that your car keeps running in an optimum condition. This is a case of preventive maintenance.

Now let’s change the previous scenario a little and imagine that you own a luxury car like a BMW. The BMW is equipped state of the art technologies like condition based service indicators for engine oil change and other filters among other things. You have driven the car for 6 months and run it for approximately 2800 kms, and then you get an indication that states you have another 200 kms left before you must change the engine oil and check the tire pressure. This is an example of predictive maintenance. You are able to prevent breakdowns as you receive service reminders which are advance warnings to fix the issue before it escalates to a major problem.

Key Differences at a glance

So how does Predictive Maintenance increase the ROI on existing infrastructure without additional costs of risky downtime? And how can we harness it?

Every manufacturer requires a combination of complex, old and new machinery in order to run their factories and produce their goods. Any equipment failure or unplanned downtime will have an adverse effect on plant operations as the necessary repairs cost time as well as money. This is because historically people have only repaired their equipment after breakdowns, causing the production line to slow or stop completely.

The goal of predictive maintenance is to predict and prevent these issues before they even happen by forecasting maintenance issues. These are based upon huge sets of data, in combination with physical sensors and monitoring values such as vibration, temperature, pressure or flow.

Modern IoT services and systems utilize machine services and repair history, to predict when a part might fall below its optimal operating efficiency. Having this data enables the scheduling of a service or part replacement ahead of failure when it has the least impact on the entire production line. This has proven to be of demonstrable business value in reducing material waste and slashing downtimes.

With this unique ability to forecast and predict when the components of industrial equipment are likely to fail so that they can be repaired, replaced before the actual breakdown predictive maintenance systems are gaining impetus. Thus cost inducing factors like damage and downtime can be avoided.

By establishing a framework that works towards predictive maintenance solutions and with the right expertise industries are implementing solutions to pinpoint where the issues lies.

Application of IIoT in Predictive Maintenance

IIoT predictive maintenance has opened up numerous possibilities for performance upgrade through total control. With reasons like, advent of Industry 4.0, rapid returns, automation, and efficiency – IIoT technologies is leading the transformation of manufacturing industry.

Let’s simplify this a little more..

Sam is a floor supervisor in a manufacturing plant; he is responsible for monitoring and maintaining a number of machines. The plant has recently installed a number of sensors on machines and connected them to the IoT platform. The sensors stream information and real time data about the machine’s vital stats. Sam monitors the data remotely and ensures that the machines are in a healthy condition.

How is he able to do this?

Step 1– The machine learning module builds models using historical data to predict future failure.

Step 2– The module proactively alerts Sam of any upcoming maintenance needs.

Step 3– Automatic maintenance tickets are generated, production schedules are automatically altered, maintenance is scheduled and technicians are assigned. Sam only has to approve the tickets and check that they have been carried through.

Summing up!

Predictive maintenance technology has been estimated to save millions of dollars worldwide by avoiding unexpected machinery accidents. It has revamped the industrial mindset of operation from ‘wait till it breaks’ to ‘complete automation’. Switching from preventive to predictive mindset has opened numerous new opportunities and ways to save costs.

With so many benefits under its banner industries are integrating and benefiting with IIoT enabled services.

Amazon, Hitachi, John Deere, Maersk- pioneer the list by switching to automation and towards a smarter tomorrow.